at the address

Vologda region, Kadui, ul. ZAPADNAIA 4

trade brand

KaduySKY Plywood Company LLC,

Kaduysky Plywood Mill LLC

The purpose of the project

- Resumption of plywood production in a new format.

- Production of a new type of product – high-quality birch large-format plywood of the FSF and FOB brand, with a volume of up to 90,000

m3/year, in the format of 1220 X 2440 mm (1250 x 2500 mm) of export quality with further expansion of production. - Organization of production of softwood sawmilling from own logging

- Solving the problem of waste disposal and recycling by building a pellet (briquette)productions.

- Obtaining heat for production by recycling bark in TMU «BERSEY» of Turkish production.

- 100% waste-free production.

- Reducing polluting emissions.

- Reducing social tension in the Kaduysky district.

- The resumption of work of the city-forming enterprise of Kadui.

- Creation of systematic tax deductions to budgets of all levels.

- Creation of new jobs.

Experience and competencies

We have the project management team that has worked at Kaduysky Plywood Mill for many years. It has accumulated extensive experience

in production and personnel management, as well as has great potential to solve problems of introducing new technologies and improving

production processes.

Since 2010, Kaduysky Plywood Mill LLC (which was part of our group of companies) has increased the production of finished plywood of the

FC and FSF brands, in the 1525×1525 mm format from 12,000 m3 to 43,000 m3 of plywood per year.

We initiated and carried out a large-scale reconstruction of the production process. Completely new production lines of branded equipment

manufacturers FEZER, TAKAYAMA, HASHIMOTO, KOSTA, BARUCCA, etc. have been put into operation. Automation of production processes has

also been implemented (automatic veneer sorting line, automatic plywood sorting line, automatic veneer filling line, etc.). All obligations for

payments for the supplied services and equipment were fulfilled in full.

We have created new jobs with decent wages, all social benefits and guarantees.

We have provided continuous staff training and professional development, as well as improving the quality of the company’s service.

The company, during its work, has acquired a stable and expanding customer base. During the period of its activity, well-known large

wholesale companies of domestic and export markets have become our permanent business partners. Shipments of manufactured products

were oriented and exported to Italy, Germany, Finland, Great Britain, the Czech Republic, Latvia, Poland, Egypt, China, the USA. Our products

have proven themselves to be the best and have occupied their part of the export and domestic plywood market.

Existing production infrastructure

- owned: A fenced production site %E2%80%93 8.8 Hectares, artesian wells %E2%80%93 1.4 Hectares, An

adjacent land plot of 3.7 Hectares, a highway %E2%80%93 0.4 Hectares, a land plot under a railway

branch %E2%80%93 2.3 Hectares - Production areas owned: the building of the Production building No. 2 – 5,017.2 m2, the building of

turning workshops 177.9 m2, the building of the boiler room – 854.5 m2, the warehouse building (former

sawmill) — 863.8 m2, the office building 531.6 m2, the building of the VNC – 148.1 m2, the building of the

KNS – 62.4 m2, warehouse buildings (forestry) — 1250.9 m2, garage building 1134.9 m2. - Pools of hydrothermal processing of raw materials – 12 compartments, with a capacity of 90 m3 of

stored raw materials in each compartment. The total load provides for up to 1000 m3; - Raw materials warehouse, with two gantry cranes KKD-16, KKS-10 – Capacity in the area of operation of

cranes up to 30,000 m3; - BERSEY 16 MW thermal oil plant – A set of one boiler unit with a capacity of 8 MW was purchased, a

reinforced concrete bookcase was installed and a heat exchanger was installed, the manufacture and

installation of boiler elements is required. The design provides for the paired operation of two boilers of

8 MW each; - Existing boiler room — two steam boilers DKVr 10/13 (2003) and DKVR 4,5/13 (1986) have been installed

and mothballed in the boiler room. Deconservation and revision are required. - The warehouse of technological chips and fuel is a concreted area of 1000 m2;

- Garage for 10 cars — existing;

- Warehouse for storage of gas and oxygen cylinders — existing;

- Local treatment facilities for industrial and stormwater runoff – an extensive network of receiving wells

are located throughout the production site and are reduced to a pressure pumping station that

transmits runoff to the sewer collector of the village of Kadui - The current railway line with a length of 1,398 m — There is a valid contract with Russian Railways.

On-site railway access roads – the installation of up to 10 wagons; - On–site driveways and platforms are paved

- Off-site access road – paved;

- On-site networks of household and drinking water supply — the f108 mm pipeline is carried out from

the existing drinking water supply of the Kadui river. The current agreement;

Household sewerage networks — the f159 mm pipeline is carried out from the existing sewage pumping

station of the enterprise to the receiving collector of the Kadui. The current agreement;

On-site industrial sewerage networks – operational; - On-site networks of industrial and technical water supply – operational;

- On-site overhead line networks-10 kV and 0.4 kV – existing, in working condition;

- On-site communication and video surveillance systems and networks — operational;

- Off-site transmission line networks-10kV –connection from the existing PS, technical specifications

issued for 2.4 MW of electricity, connection of the site with two lines of FSHB -1.2; - Off-site telephony networks — active;

- The fencing of the territory is a metal fence.

- 10 kV switchgear and 10/o transformer substations,4 kV — operational;

- VNS fire extinguishing pumping station with 2 fire tanks — operational;

- Turning workshops are active.

- Artesian wells 36 and 38 meters are operational.

The need for raw materials and supplies

- The raw materials for the production of plywood are

round hardwood (birch ridge) according to GOST

9462-88 «Timber for peeling», in ridges from 1.4 to 5.5

m, one, two and three multiples of the length of the

churak, with an average diameter of Dsr = 220 mm. - The provision of raw materials is provided from its

own logging allocated by the regional Government

within the framework of a «Priority investment

project» in the amount of 300 thousand m3 /year., as

well as the purchase of a ridge from loggers of the

Vologda region. - The supply of raw materials is provided by rail and

road transport.

Project Performance achieved

- The project of plywood production with a volume of 40,000 m3/year, the production of laminated plywood of 8×4 ft and 4×8 ft, followed by an increase in output to 90,000 m3/year – stage «P» has been completed.

- The pellet production project with an output of 90,000 tons/year, followed by an increase in output to 180,000

tons/year — completed. - The examination of the projects — completed.

- The project of the sanitary protection zone — completed.

- Coordination of projects with Rospotrebnadzor — completed.

- The sanitary and epidemiological conclusion of Rostechnadzor — received.

- The construction permit was received on 07/12/2023.

- The construction of a new workshop is expected to take 6-8 months (part of the building has been purchased).

- The production of the main technological equipment is expected to take 10-15 months.

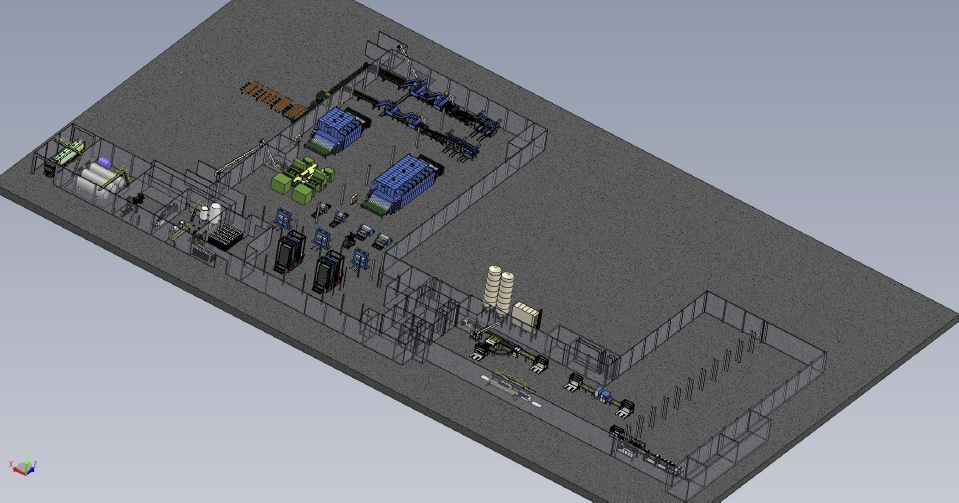

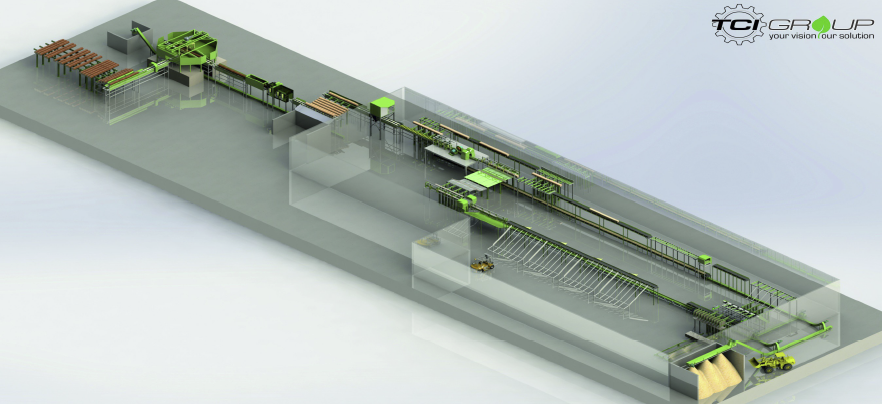

- The issue of the organization of sawmilling has been worked out, 3D models have been developed

- A 5Ha land plot was acquired for the production of sawmilling and drying of lumber.

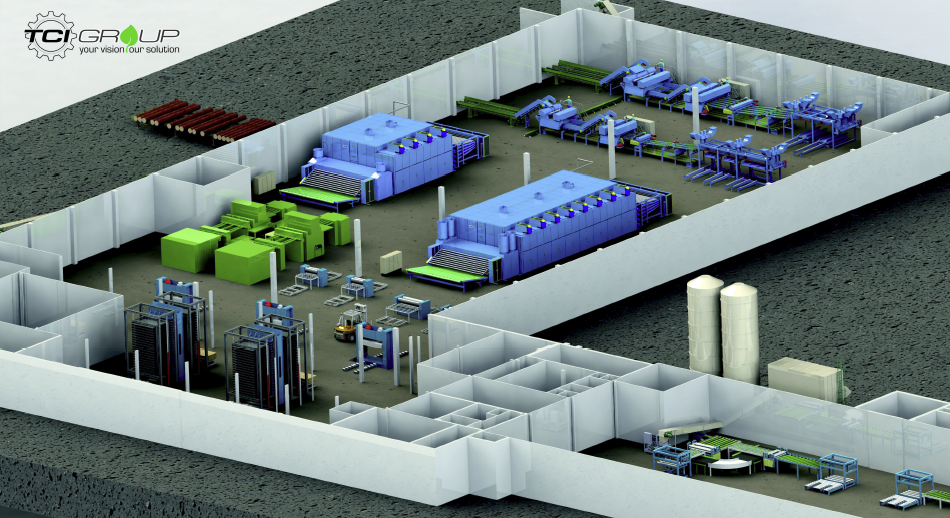

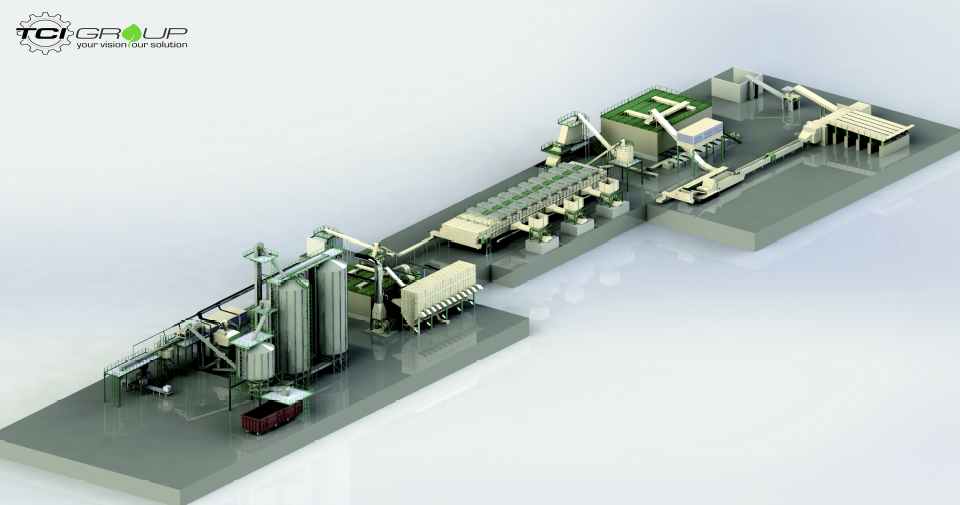

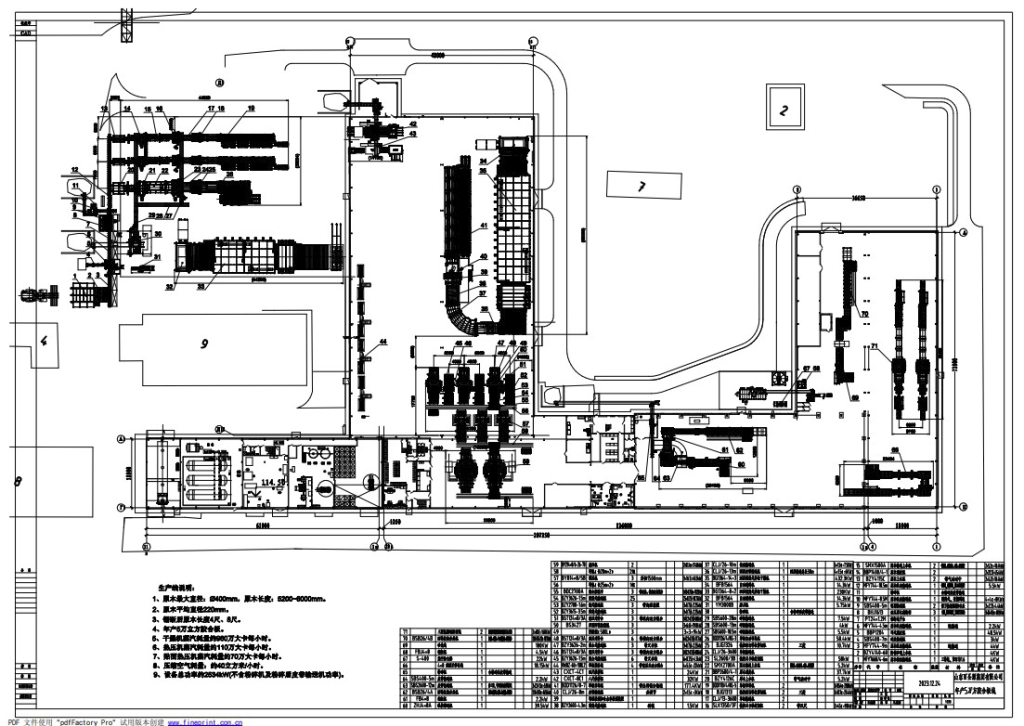

Plywood production 40 thousand m3/year

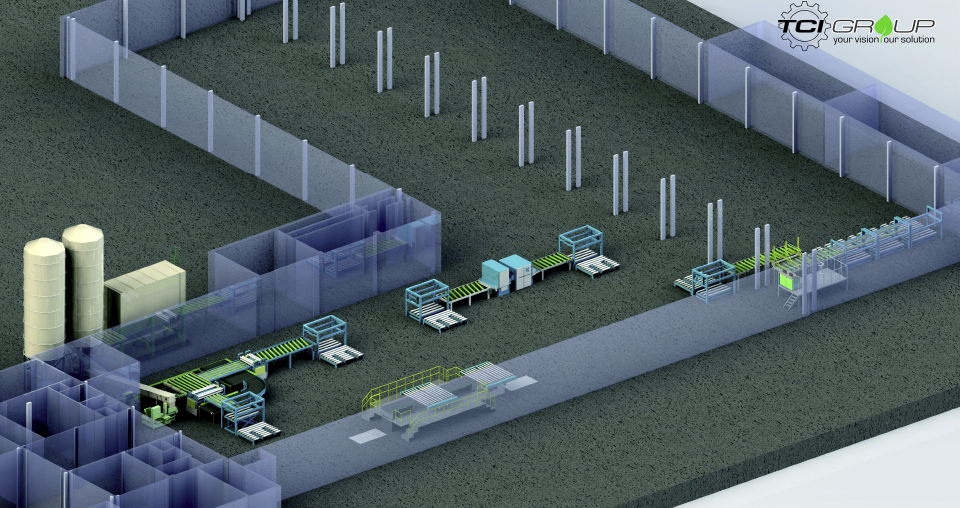

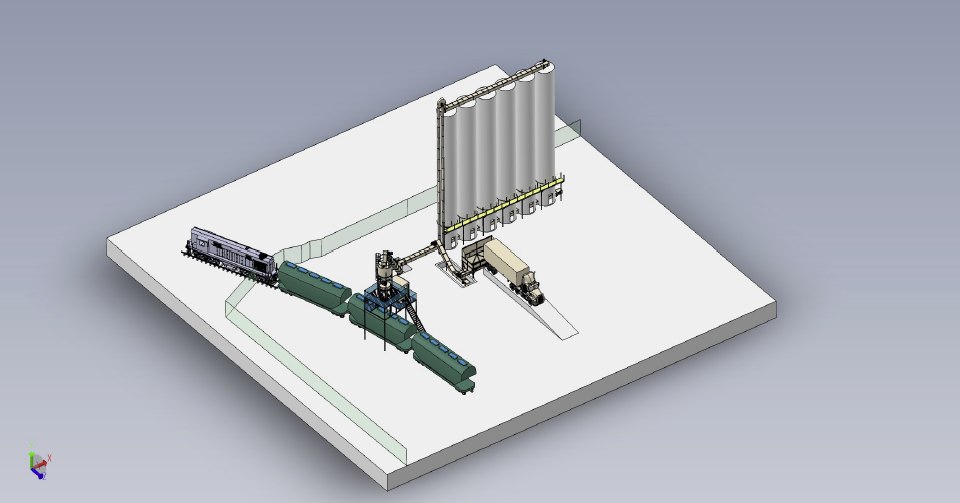

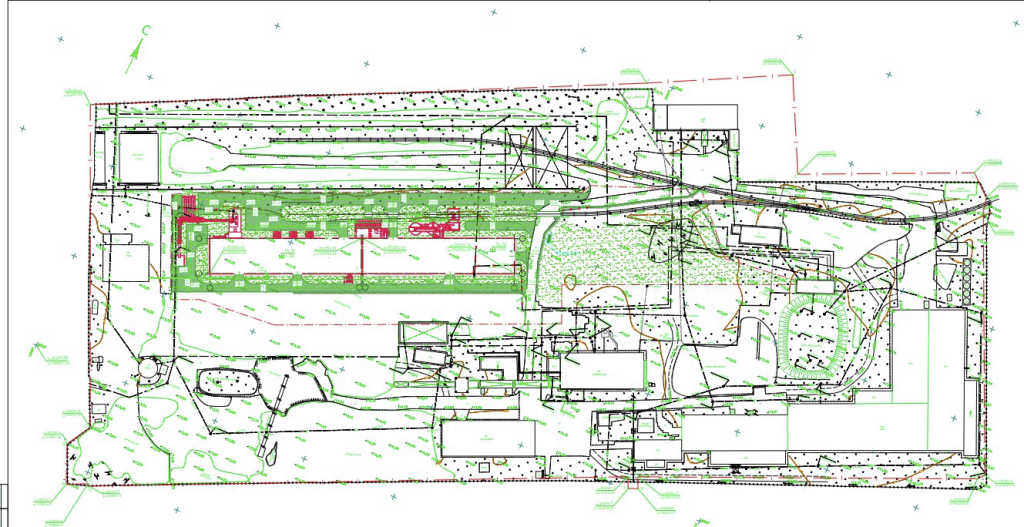

Temporary storage warehouse for pellets

Production of sawmilling and drying of lumber 150 thousand m3/year, with an increase to 250 thousand

Sawmill production 150 thousand m3/year

Plywood production

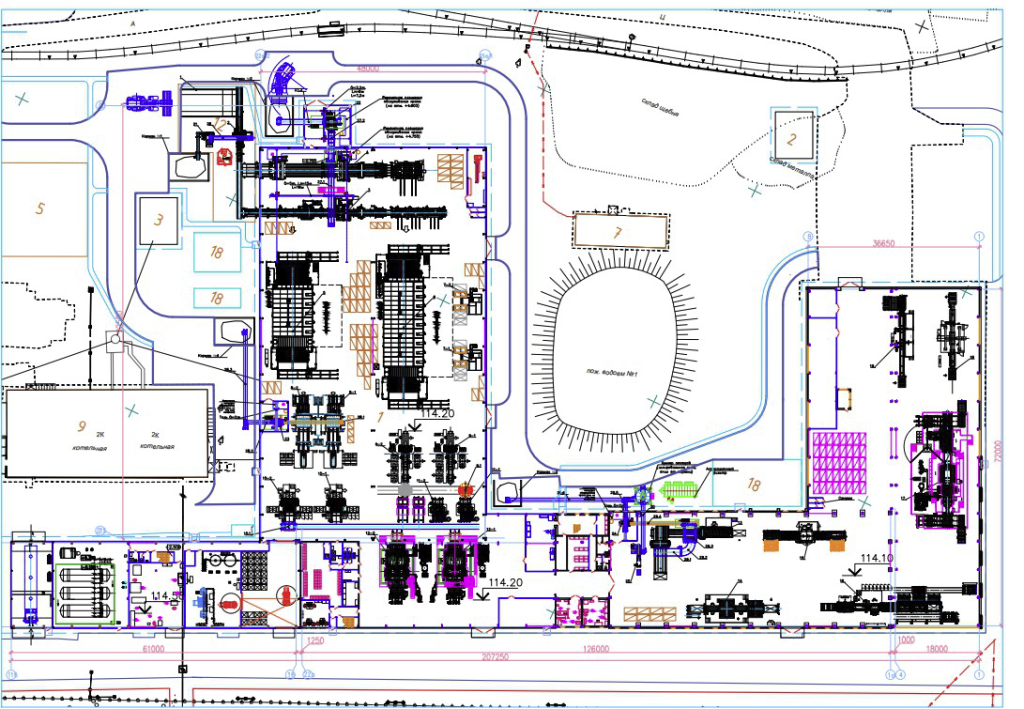

Situational plan of plywood production

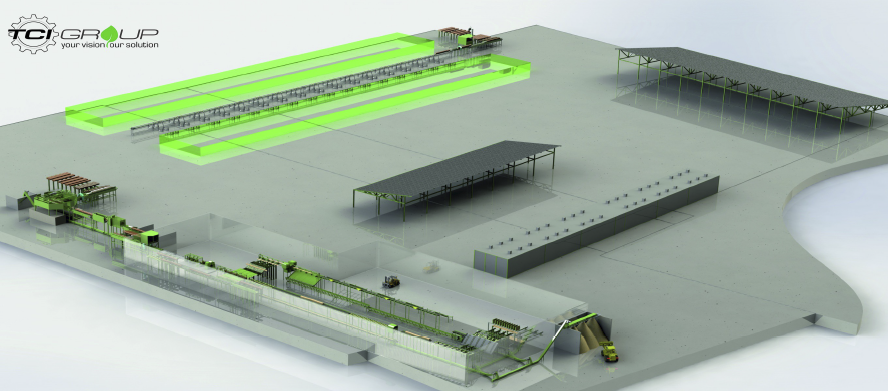

Expansion of plywood production

Situational plan of pellet production

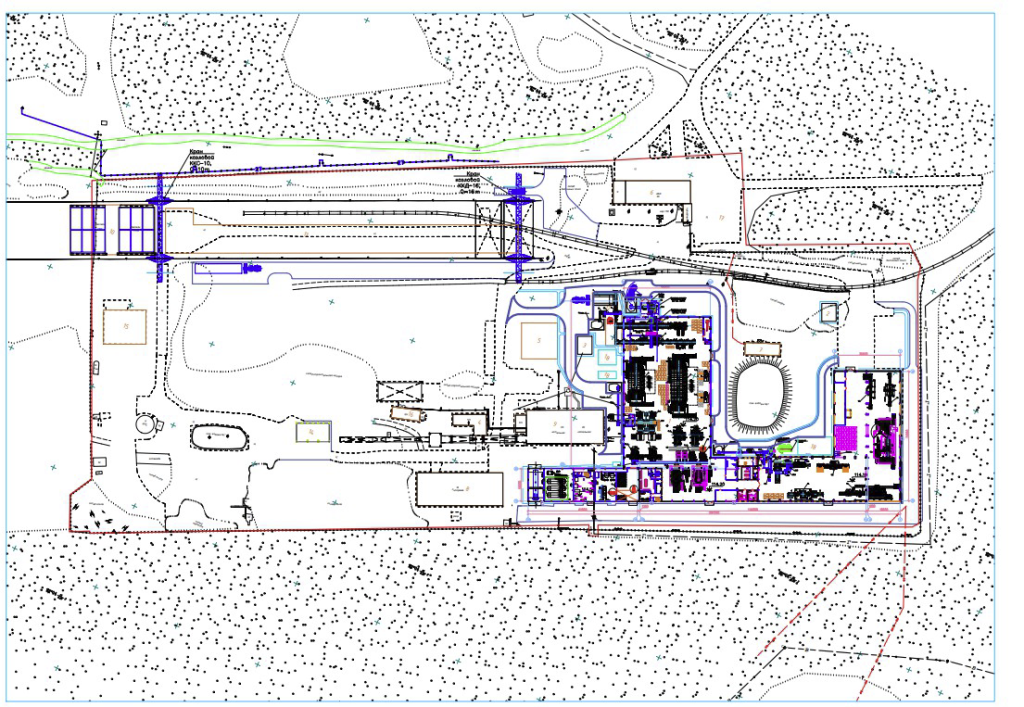

Situational plan of the land plot